Pipelines are critical arteries in the energy industry, ensuring the smooth and efficient transport of oil products. However, one of the biggest challenges facing these systems is the formation of undesired solids like paraffin wax and asphaltenes, which can significantly hinder flow and lead to costly downtime. Proactive deposit prevention and remediation with specialized chemical solutions are essential to maintaining consistent operations. Here, we explore how Ideal Energy Solutions LLC’s chemical products help keep pipelines clear of these obstructive deposits, minimizing downtime and enhancing operational efficiency.

Understanding Paraffin Wax and Asphaltene Deposits in Pipeline Operations

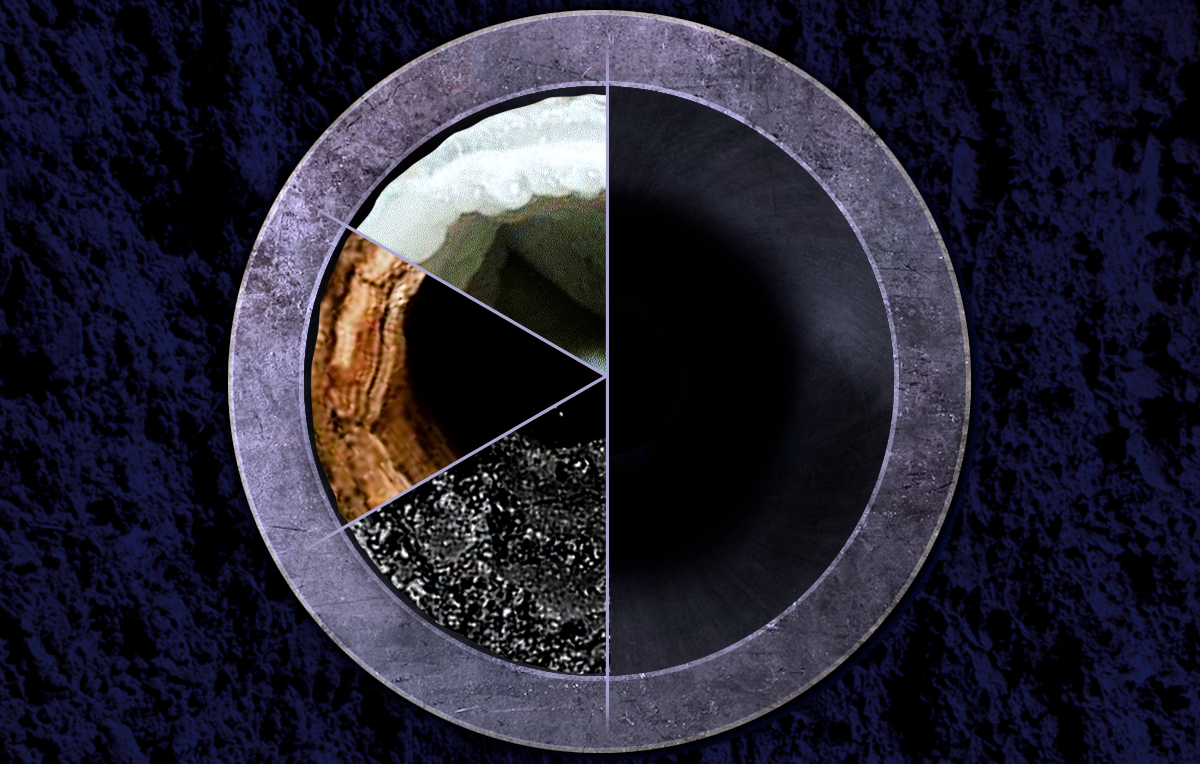

Paraffin wax and asphaltenes are common byproducts in oil production. These solids can precipitate out of the transported products under certain conditions, such as temperature drops or pressure changes, and adhere to pipeline walls. Over time, this build-up restricts flow, reduces operational efficiency, and increases the risk of full blockages that can bring pipeline operations to a standstill. Left unchecked, these deposits not only lead to unplanned shutdowns but also accelerate wear on pipeline components, increasing maintenance needs and overall operating costs. Preventing these issues is essential to avoid interruptions and maintain efficient flow.

How Ideal Energy Solutions LLC’s Products Tackle Wax and Asphaltene Build-Up

Ideal Energy Solutions LLC offers a range of chemical products specifically formulated to prevent and remediate wax and asphaltene deposits in pipelines. Recommended chemical treatments are customized to address the unique conditions of each pipeline, such as fluid composition, temperature, and pressure, maximizing their effectiveness and impact. Our primary solutions include:

When wellbore blockages occur, WellRenew® provides a robust solution. It migrates to blockages, displacing lighter fluids and breaking down deposits into manageable substances. WellRenew® is effective across a wide range of temperatures and well depths, ensuring versatility and effectiveness in various scenarios.

For flow lines and pipelines, PipeRenew® offers a tailored approach to remediation. It targets and displaces blockages, penetrates deep into deposits, and neutralizes paraffin adhesion. PipeRenew® is particularly effective at low temperatures and can be used in pipelines of any size and depth, whether onshore or offshore.

PigRenew® combines mechanical and chemical cleaning properties to target deposits directly, ensuring thorough cleaning even in extreme conditions. It breaks down deposits into easily removable substances and leaves a protective film that prevents future deposits and corrosion. PigRenew® is also completely soluble, meaning that should it become stuck, it will dissolve in place, making it a highly efficient and effective pigging solution that provides long-term protection for your pipelines.

For those looking to maintain pipeline health and prevent blockages, LamFlo® is an excellent choice. It breaks apart and suspends paraffin wax and asphaltenes, ensuring smooth and uninterrupted flow. LamFlo® is biodegradable, BTEX-free, and non-hazardous, making it ideal for both onshore and offshore applications.

Each of these products is formulated with specific operating conditions in mind, providing a tailored solution to prevent the recurring issues that wax and asphaltenes can cause.

Case Study: Effective Remediation of Wax and Asphaltene Build-Up

In a recent application, one of our clients was experiencing recurring blockages due to severe paraffin wax and asphaltene build-up. Frequent shutdowns for cleaning were resulting in production losses and added operational costs. After consulting with our team, the client opted for a thorough cleaning with PipeRenew® and adopted a regular preventative application of LamFlo®. Following implementation, the client reported a reduction in blockages and significant improvements in flow rate. The success of this chemical treatment helped them maintain uninterrupted operations and cut back on maintenance expenses, demonstrating the real-world impact of proactive chemical deposit management.

In a recent application, one of our clients was experiencing recurring blockages due to severe paraffin wax and asphaltene build-up. Frequent shutdowns for cleaning were resulting in production losses and added operational costs. After consulting with our team, the client opted for a thorough cleaning with PipeRenew® and adopted a regular preventative application of LamFlo®. Following implementation, the client reported a reduction in blockages and significant improvements in flow rate. The success of this chemical treatment helped them maintain uninterrupted operations and cut back on maintenance expenses, demonstrating the real-world impact of proactive chemical deposit management.

Long-Term Benefits of Specialized Deposit-Control Chemicals

Incorporating chemical solutions into regular pipeline maintenance offers long-term economic and operational benefits. Proactive deposit management not only keeps pipelines flowing smoothly but also reduces risks associated with unplanned shutdowns. With fewer interruptions, operators can achieve better production consistency, lower maintenance costs, and enhanced overall safety. Compared to the expenses of addressing severe blockages or replacing damaged pipeline sections, preventive chemical treatments represent a highly cost-effective approach.

Ideal Energy Solution LLC’s products specifically address wax and asphaltene management, providing a reliable method for preserving pipeline integrity and optimizing operational uptime.

Partnering with Ideal Energy Solutions for Effective Pipeline Maintenance

Ideal Energy Solutions’ expertise in pipeline remediation and maintenance provides a valuable resource for companies looking to minimize downtime and prevent deposit-related disruptions. Our team is committed to offering tailored solutions that meet each client’s unique challenges, backed by technical support and consultation to ensure optimal application and effectiveness. With our innovative products and expert guidance, we can help you keep your pipelines free of unwanted deposits, ensuring smooth, efficient operations.

Wax and asphaltene deposits are a persistent challenge in the energy industry, but with the right chemical solutions, companies can effectively prevent and manage these issues. Ideal Energy Solutions LLC’s specialized remediation and maintenance chemical solutions provide essential support for preventing wax and asphaltene deposits, keeping pipelines operational and minimizing costly downtime.

To learn more about our solutions and how we can support your pipeline maintenance needs, reach out to us today.