When an oil and gas pipeline reaches the end of its service life, the proper steps must be taken to safely remove it from service. This process, called decommissioning or abandonment, involves disconnecting the pipeline from active service and removing every trace of oil or natural gas.

Improper pipeline abandonment can have deadly consequences. In 2017, an explosion at a house in Colorado killed two people and destroyed two homes. The National Transportation Safety Board determined that fugitive natural gas from an improperly abandoned pipeline was the probable cause of the explosion. The pipeline’s original owner had not properly abandoned the line, and local authorities approved the home’s construction without thoroughly investigating the network of oil and gas gathering pipes in the area.

When pipelines are safely decommissioned or abandoned, they pose little threat to the general public or the environment. Pipelines change ownership frequently and there is often little oversight to the decommissioning and abandonment process. Ultimately, pipeline owners are responsible for cleaning and properly decommissioning their lines. The best way for operators to prevent future environmental damage, human harm or reputational risk is to thoroughly clean pipelines before decommissioning.

Pipeline Decommissioning and Abandonment

Pipelines are decommissioned when there is no longer a need for them, or when they reach the end of their service life. Oil and gas pipelines are typically made of cast/wrought iron, steel and plastic. While modern plastic pipelines have a long service life, iron and steel pipes eventually rust or degrade and need to be taken out of commission.

Pipeline decommissioning and abandonment is a multi-step process that involves hot work. The first step in decommissioning is removing all oil from the pipeline, typically through nitrogen purging or pigs. After the oil is removed, the pipeline is chemically treated and wiped to remove all hydrocarbon residue. Once the pipeline is clean, it is disconnected from active facilities and sealed to prevent oil from reentering the line.

Decommissioned pipelines may be used again in the future, while abandoned pipelines will never be used again. This process is called abandonment-in-place, as the pipelines will remain where they are. Abandoned pipelines are sealed and filled with a specially designed concrete material to prevent liquids and gasses from entering the line, or line collapse. Leaving abandoned pipelines in place, rather than excavating them, minimizes environmental disruption and reduces the risk of ground instability or compaction. Both abandoned and decommissioned pipelines should be continuously monitored by their owners and/or operators.

Pipeline Regulations

In the United States, pipeline operation is regulated by the Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA), with additional oversight from the Federal Energy Regulatory Commission (FERC) and the Department of the Interior’s Bureau of Safety and Environmental Enforcement (BSEE) for offshore pipelines. States can also place additional and more stringent requirements on pipeline operations.

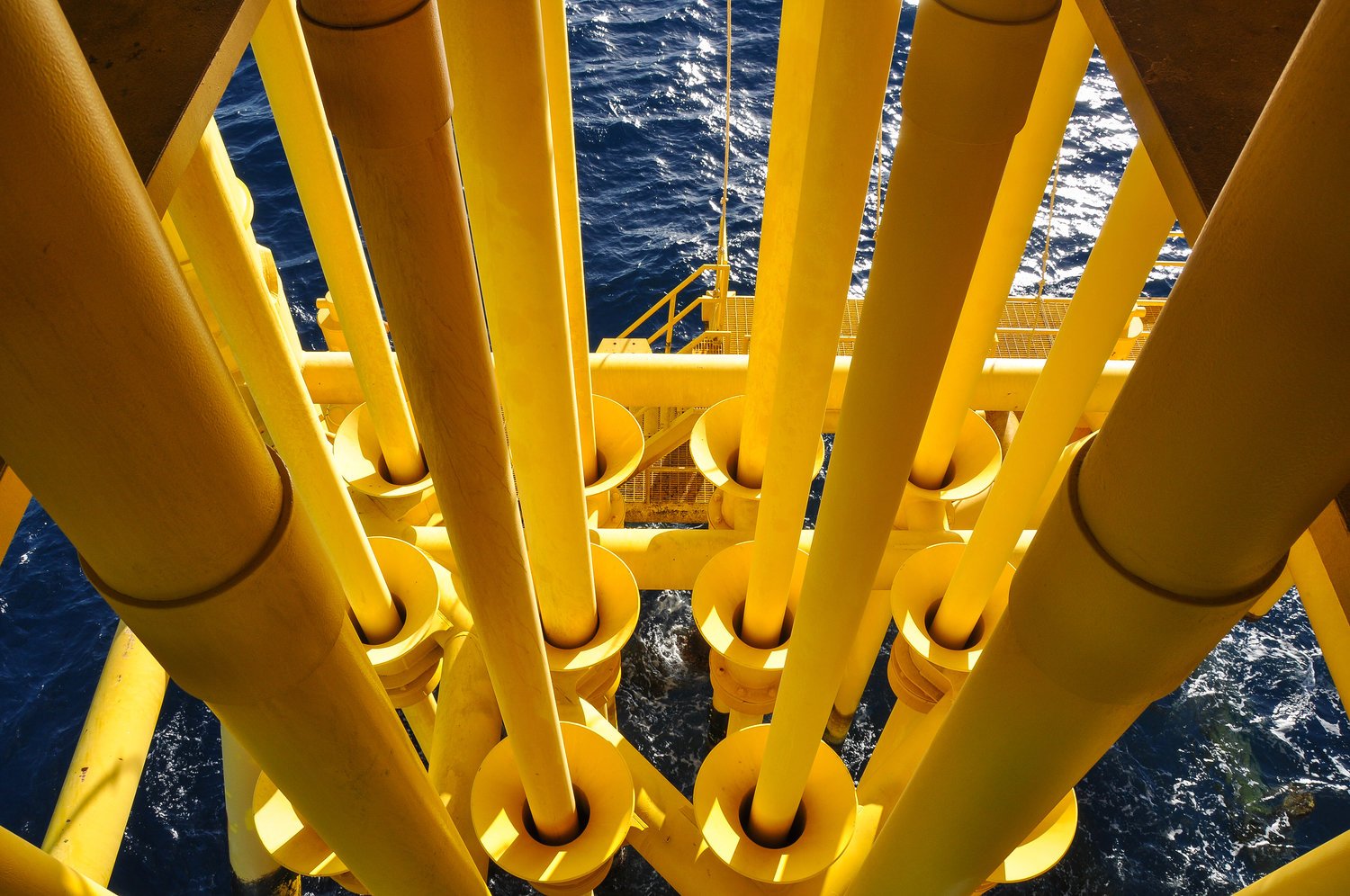

Offshore Pipeline Decommissioning and Abandonment

The same process is used for decommissioning and abandoning onshore and offshore pipelines. However, working offshore is more complex and costly than working on land. Transporting workers and materials to platforms in the ocean is expensive, and the environmental risks are greater. Offshore pipeline decommissioning work requires numerous inspections to ensure marine life, navigation and commercial fishing activities are not impacted by the abandoned pipeline.

Properly cleaning and removing all oil from abandoned offshore pipelines is a critical step in preventing oil spills. In 2021, Hurricane Ida caused oil to leak from an abandoned 12-inch pipeline off the coast of Louisiana that still had oil inside. The spill created a 14-mile long oil slick. A 2018 report from the Bureau of Ocean Energy Management estimates that roughly 40% of offshore pipeline spills were related to natural causes like hurricanes and mudslides. Currently, inspecting abandoned pipelines to ensure all oil is removed is not required or overseen by the government, and is left to the pipeline’s operator to handle.

Preparing Pipelines for Decommissioning and Abandonment

Cleaning pipelines and removing all traces of oil, hydrocarbons and volatile oil compounds (VOCs) is required for safe and responsible pipeline decommissioning and abandonment. This step keeps workers safe during the decommissioning process and protects humans and the environment from potential leaks.

Ideal Energy Solutions, LLC’s LamKleen® detergent is a highly effective pipeline cleaning agent. LamKleen® is an alkaline-based detergent that removes VOCs that remain in pipelines or equipment. It is a liquid, non-hazardous, pre-packaged, ready-to-use blend of alkaline salts and biodegradable surfactants. It readily penetrates paraffin and asphaltene deposits, and solubilizes and emulsifies old oil, removing it from the pipeline walls. LamKleen® is the ideal cleaning agent for preparing pipelines for decommissioning and abandonment.