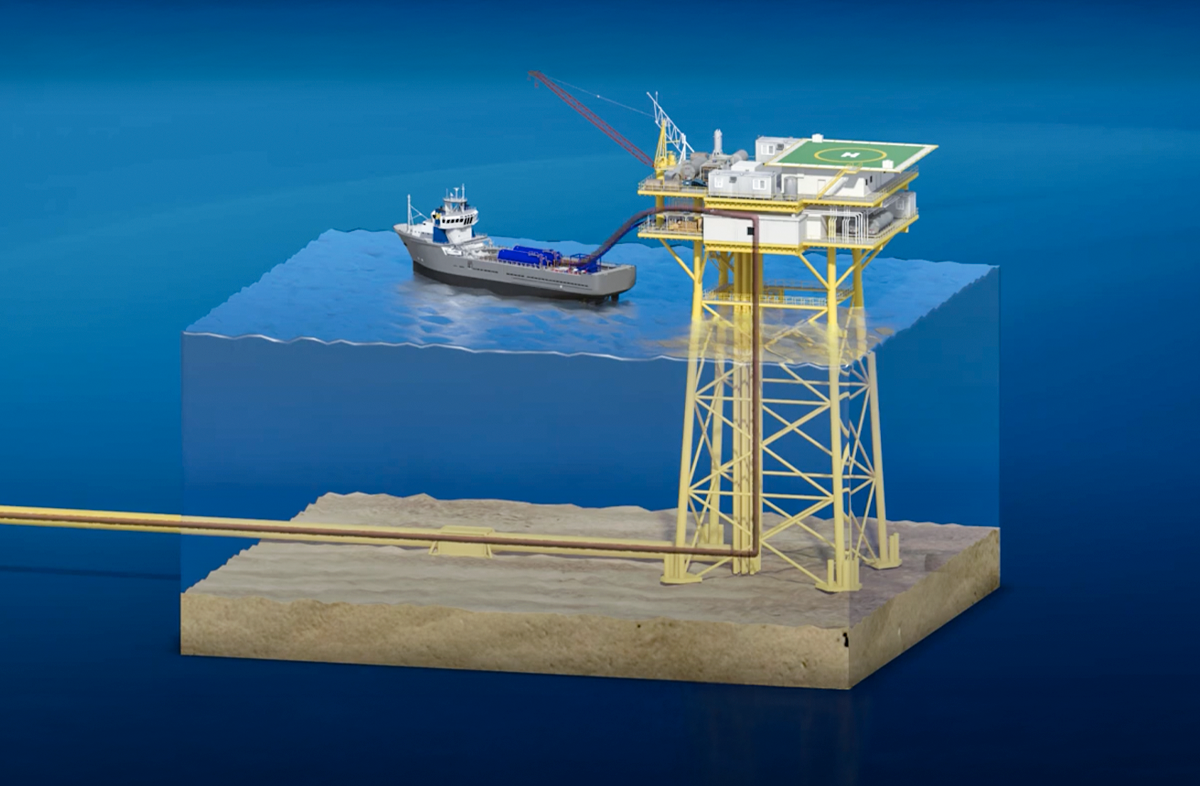

Offshore pipelines play a critical role in the energy industry by transporting oil and gas from offshore platforms to shore-based facilities. However, the environment in which they operate presents unique challenges, especially when it comes to maintaining smooth flow and ensuring pipeline integrity. The complexities of sub-sea pipelines stem from their exposure to harsh conditions like extreme pressures, fluctuating temperatures, and the presence of challenging deposits like paraffin wax and asphaltenes. These factors, if not managed properly, can cause serious operational disruptions, reducing efficiency and increasing costs.

The Complexities of Offshore Pipelines

Temperature gradients: The temperature of fluids traveling through offshore pipelines can vary dramatically between the surface and the seabed. These fluctuations can lead to wax deposition and the formation of blockages in the pipe.

Hydrate formation: At lower temperatures, water in the pipeline can form hydrates, which can block the flow entirely.

Corrosion: The harsh, salt-laden seawater environment can cause corrosion inside the pipeline, leading to a risk of leaks and ruptures.

Paraffin wax and asphaltene deposits: As the oil moves through the pipeline and cools, waxes and other solidified components can precipitate, leading to buildup and flow restrictions.

The Types of Deposits: Paraffin Wax and Asphaltenes

Two of the most common issues in offshore pipelines are paraffin wax and asphaltenes, both of which can disrupt the flow of oil and gas through sub-sea pipelines.

Asphaltenes: Asphaltenes are a complex group of hydrocarbons that are typically heavier and more polar than other components of crude oil. When the crude oil experiences changes in temperature, pressure, or composition, asphaltenes can precipitate out and form deposits. These deposits can clog the pipeline, affecting flow and leading to operational disruptions.

Both paraffin wax and asphaltene buildup can be difficult to manage, and if left untreated, they can lead to pipeline failures, equipment damage, and costly repairs.

Solutions for Sub-Sea Pipelines from Ideal Energy Solutions LLC

PipeRenew®

PipeRenew® is a powerful solution formulated to remediate and prevent the future deposition of paraffin wax and other solidified materials in offshore pipelines. By using a unique blend of surfactants and solvents, PipeRenew® breaks down and dissolves stubborn wax buildups, restoring normal flow and improving overall pipeline efficiency. Whether used for routine maintenance or emergency remediation, PipeRenew® is a reliable choice for managing paraffin wax issues in sub-sea pipelines.

PigRenew®

PigRenew® is a chemically-infused pig that serves as a superior alternative for traditional pipeline pigs. This pig is infused with chemicals that help dissolve wax and asphaltene deposits, allowing it to clear blockages effectively while leaving behind a treatment that prevents future buildup. PigRenew® can treat the pipeline directly during the pigging process and will dissolve in place should it become stuck, eliminating the need for costly retrieval.

LamFlo®

LamFlo® is a viscosity reducer designed to break apart and suspend paraffin wax and asphaltene deposits. By altering the physical properties of the deposits, LamFlo® prevents the wax and asphaltenes from depositing on pipeline walls, maintaining a smooth flow through the pipeline. This solution is ideal for operators who want to proactively prevent buildup and ensure consistent flow without the need for frequent remediation.

LamFlo+CI™

LamFlo+CI™ is an enhanced version of LamFlo®, incorporating corrosion inhibitors to protect the pipeline from the damaging effects of corrosive substances. In addition to preventing the formation of wax and asphaltene deposits, LamFlo+CI™ also provides an added layer of protection against corrosion, ensuring that pipelines remain structurally sound and resistant to the harsh sub-sea environment.

LamKleen®

LamKleen® is designed to clean pipelines and equipment, preparing them for maintenance or abandonment. Its low surface tension allows it to penetrate deposits and cracks, solubilizing and emulsifying old oil to remove hydrocarbon residuals.

The emulsifying action from LamKleen® also reduces VOCs by incorporating hydrocarbons into the water phase, allowing for a deep clean prior to servicing.