The development of thermoplastic composite pipes opens up new possibilities in the oilfield, particularly offshore. The uni-directional carbon fiber PA12 tape VESTAPE PA12-CF (PA12) is a nonmetallic corrosion-resistant solution that incorporates carbon fibers providing strong resistance to fatigue-based failures, making it suitable for dynamic applications.

Using thermoplastic pipe in offshore oil operations has numerous benefits. The new type of pipe can improve safety, prevent corrosion, and improve operational efficiencies. It also contributes to ESG goals by reducing greenhouse gas emissions.

TCP approval for offshore capabilities

Thermoplastic Composite Pipe (TCP) earned full certification from global classification society DNV for development by Strohm and Evonik. This announcement follows a five-year investment testing program demonstrating how TCP performs after operating in harsh chemical, thermal, and mechanical environments.

Using the Netherlands Aerospace Centre’s (NLR) composite testing facilities for parallel dynamic and long-term testing, the two companies achieved faster results than conventional sequential testing. Results showed the stiffness of the carbon fibers works well in deepwater service and operating pressures of up to 10,152 psi and temperatures up to 176ºF.

The approval from DNV confirms that Strohm’s TCP is suitable for dynamic sweet and sour hydrocarbons, water, and gas injection applications. Application expansion plans extend to hydrogen and carbon capture, utilization, and storage.

Read more about thermoplastic composite pipe, its approval by DNV, and its capabilities in Offshore Magazine.

TCP is a less corrosive option to steel

Corrosion is a significant and costly issue in production; second only to fire, it is the most serious threat and cause of monetary loss in production. The introduction of TCP proves a better solution to the steel pipes that were once the only option.

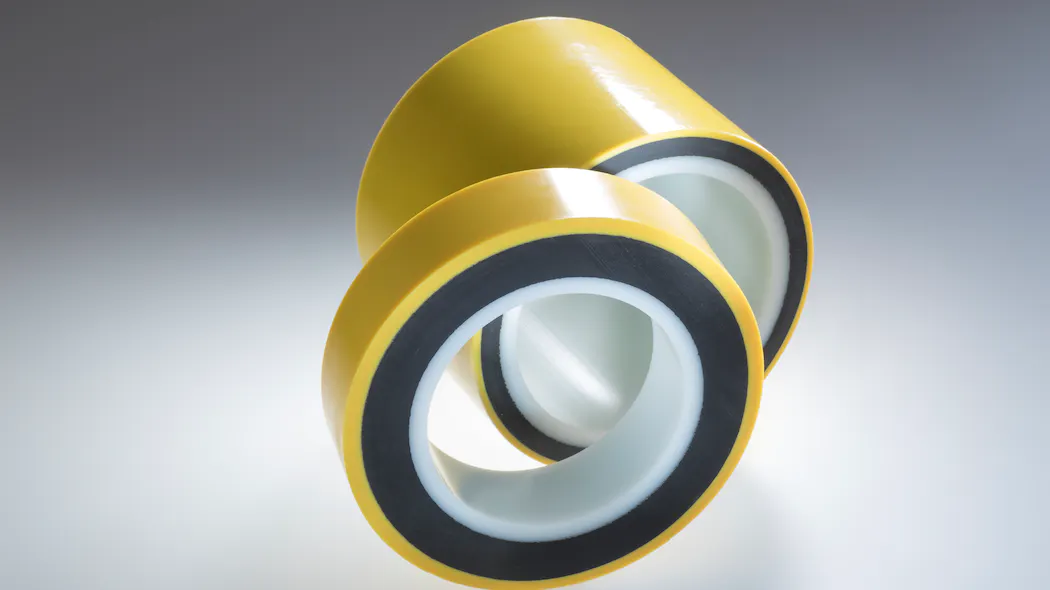

The breadth of applications for TCP is promising, including flowlines, risers, jumpers, expansion spools, injection lines, and much more. The solid pipe wall of TCP is constructed from glass or carbon reinforcement fiber and thermoplastic polymeric materials. The spoolable pipe is 80% lighter than steel and adaptable to production-specific requirements.

The value added by using TCP goes deep. It eliminates corrosion, the problems caused by corrosion, and the need to employ mitigating practices like adding inhibitors, pigging, and inspection and maintenance requirements. TCP significantly reduces installation costs because the lightweight material is easier and less expensive to transport, and its flexibility also allows for easier installation.

Read more about TCP, its installation, and applications in Offshore Magazine.

Use of TCP greatly reduces greenhouse gas emissions

A report comparing TCP with carbon steel pipe shows a reduction in GHG emissions of 30-60% when using TCP over steel pipe. The study included direct and indirect GHG emissions, including material extraction and production to the pipelines end of life stage and all activities associated with the product’s lifecycle. The ease of transport and installation dramatically contributes to the lower carbon footprint of TCP.

For more information about the carbon footprint report on TCP, read Offshore Magazine.