Although consumers in end-use applications may not be aware of it, a large volume and wide scope of research and development in green chemistry technologies has been under way for some time. This work is proving that green chemistry is not a performance limitation imposed on traditional products. Our development of green chemistry solutions is driven not by statutory imperatives, but by the great potential these technologies present.

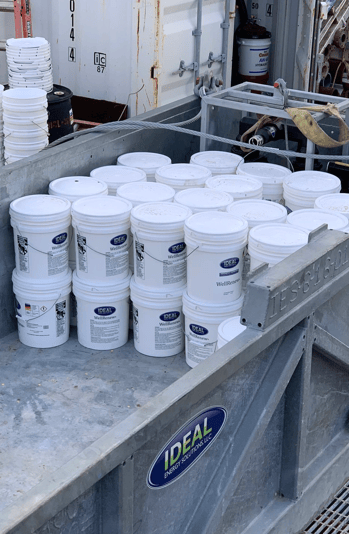

In fact, our clients are already benefiting from green chemistry products we have proven in commercial use. Our technical experts have developed the world’s most environmentally responsible family of flow assurance preventative and remediation chemical solutions. Two of our products, PipeRenew® and WellRenew®, are Green Seal Certified®, meeting rigorous performance, health and environmental criteria.

What is green chemistry?

On the surface, the answer is simple; green chemistry is a radical change in the way chemicals are designed. Also known as sustainable chemistry, it reduces or eliminates the use or generation of hazardous substances.

What are its advantages?

Green chemistry reduces pollution at its source by minimizing or eliminating the hazards of chemical feedstocks, reagents, solvents, and products. This is unlike cleaning up pollution (also called remediation), which involves treating waste streams (end-of-the-pipe treatment) or clean-up of environmental spills and other releases.

Green chemistry applies across the lifecycle of a chemical product, including its design, manufacture, use, and ultimate disposal. It is a philosophy that applies to all areas of chemistry, not a single discipline.

Green chemistry offers enormous advantages over traditional chemistry as it:

- Prevents pollution at the molecular level

- Applies innovative scientific solutions to real-world environmental problems

- Results in source reduction because it prevents the generation of pollution

- Reduces the negative impacts of chemical products and processes on human health and the environment

- Lessens and sometimes eliminates hazards from existing products and processes

- Designs chemical products and processes to reduce their intrinsic hazards

Green chemistry's 12 principles define the breadth of its concept:

- Prevent waste: Design chemical syntheses to prevent waste. Leave no waste to treat or clean up.

- Maximize atom economy: Design syntheses so that the final product contains the maximum proportion of the starting materials. Waste few or no atoms.

- Design less hazardous chemical syntheses: Design syntheses to use and generate substances with little or no toxicity to either humans or the environment.

- Design safer chemicals and products: Design chemical products that are fully effective, yet have little or no toxicity.

- Use safer solvents and reaction conditions: Avoid using solvents, separation agents, or other auxiliary chemicals. If you must use these chemicals, use safer ones.

- Increase energy efficiency: Run chemical reactions at room temperature and ambient pressure whenever possible.

- Use renewable feedstocks: Use starting materials (also known as feedstocks) that are renewable rather than consumable. The source of renewable feedstocks is often agricultural products or the wastes of other processes; the source of consumable feedstocks is often fossil fuels (petroleum, natural gas, or coal) or mining operations.

- Avoid chemical derivatives: Avoid using blocking or protecting groups or any temporary modifications if possible. Derivatives use additional reagents and generate waste.

- Use catalysts, not stoichiometric reagents: Minimize waste by using catalytic reactions. Catalysts are effective in small amounts and can carry out a single reaction many times. They are preferable to stoichiometric reagents, which are used in excess and carry out a reaction only once.

- Design chemicals and products to degrade after use: Design chemical products to break down to innocuous substances after use so that they do not accumulate in the environment.

- Analyze in real time to prevent pollution: Include in-process, real-time monitoring and control during syntheses to minimize or eliminate the formation of by-products.

- Minimize the potential for accidents: Design chemicals and their physical forms (solid, liquid, or gas) to minimize the potential for chemical accidents including explosions, fires, and releases to the environment.

Since 2013, Ideal Energy Services, LLC has applied these principles to the development of cleaner, smarter, higher-performing alternatives to traditional chemical solvents hazardous to people and the environment. Our clients benefit from more effective and efficient solutions to their most difficult challenges. Equally important, their stakeholders enjoy the twin benefits of higher business performance and greater environmental responsibility, made possible by green chemistry.

-1.png)